Rotaj Aluminium Establishment

Shaping Your Vision with Glass and Aluminium Excellence

BUILDING THE FUTURE

Rotaj Aluminum establishment has specialized in aluminium and galzed structures, architectural metel works, stainless steel, and composite metel works. Service offered include conceptual designing, feasibility study, estimation, fabrication and installation.

Rotaj Aluminum standards for quality, by regular in-progress inspections at the various levels of manufacuring, the company ensures that all the parameters at all levels are always set to prescribed International standards.Rotaj Aluminum is an ISO 9001:2000 and ISo 14001 certified company having office Abu Dhabi.

Qualified engineers, skilled designers, experienced fabricators and installers familer with state-of-the-art technology are part of the Rotaj Aluminium team.Rotaj Aluminium uses the latesr computer-aided technology in design and production systems for the cost effective soluutions, with the highest quality specifications.

SERVICES WE OFFER

- Conventional & Unitized Curtain Wall Systems

- 2-Way & 4-Way Structural Glazing Facades

- Architectural Composite and Solid Panel Cladding

- Aluminium & Glazed Doors, Windows & Partitions

- Shop Fronts

- Spider Systems & Space Frame Structures

- Skylights, Canopies, and Conservatories Handrails

- Boundary Walls, Gates, Kitchen Cabinets

OUR SCOPE OF WORKS

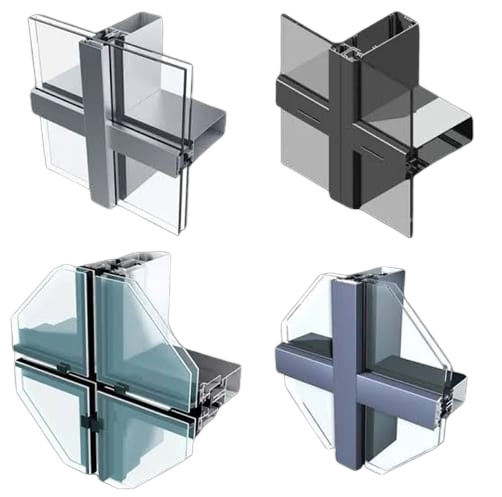

Curtain Wall

Curtain walls is one of the ways to protect

your building from harsh outdoor elements.

a curtain wall system is thin and light

weight, usually aluminum and glass.

Skylight

A skylight can provide lighting, ventilation, views, and sometimes emergency egress. A skylight can provide your home with day lighting and ventilation.

Pergola & Canopy

A pergola is an outdoor garden feature forming a shaded walkway, passageway, or sitting area of vertical posts or pillars that usually support cross-beams.

Hand Rail

Handrails are commonly used while ascending or descending stairways and escalators in order to prevent injurious falls. Handrails are typically supported by posts or mounted directly to walls

Shop front

Shopfront is the facade or entryway of a retail store located on the ground floor or street level of a commercial building, typically including one or more display windows.

Shower Door

shower door is a system that consists of two or sometimes three tempered glass. These panels are set inside of two aluminium tracks, one at the top and one at the bottom.

WHAT WE DO

Aluminium & Glass Fabrication

We are specialized in aluminium and galzed structures, architectural metel works, stainless steel, and composite metel works. Service offered include conceptual designing, feasibility study, estimation, fabrication and installation.

PRODUCTS WE OFFER

Aluminium & Glazed Structures

Kitchen Cabinets with HPL Panels, MDF Melamine

Cast Aluminium Railings, Gates & Boundary Walls

OUR CORE VALUES

Rotaj Aluminum’s strength grows from a distinct culture that is founded on the core values of the business

We deliver leading facades and decorative products and solutions manufactured from aluminium glass

Stainless steel products under one roof.

We provide fast and precise delivery throughtout the United Arab Emirates.

We support our customers with dedicated professionals who remain abreast of industry-related global

development.

We seek to optimise solutions for our customers.

We harness world-class information technology to ensure high levels of quality service.

HEALTH AND SAFETY

Safety has always been Rotaj Aluminium’s top priority. Rotaj Aluminium believes that every accident is preventable and this philosophy has been embedded into every Rotaj Aluminium project through a combination of technical field procedures, safety gear, and ongoing training programs. Our safety philosophy is based on the belief that every individual is entitled to a safe and healthy place to work.

Rotaj Aluminium establishment an award-winning Accidenty prevention programm that includes formal safety trainings, Inspections, audits and formalized system of reporting. We recognize that accident

prevention is a line management responsibility. That responsibility is shared at every level of our organization, from the chairman all the way to the work force. Rotaj Aluminium trains its managers,

supervisors and employees to identify aand correct unsafe conditions and more importantly unsafe work practices.

Rotaj Aluminium’s commitment to zero accidents extends to every aspect of a project from planning to completions and from the board room to the field crew. For clients, the most tangible benefit of Rotaj

Aluminium’s safety efforts is better performance on the project and a clear reduction of unanticipated costs. Rotaj Aluminium also asks its sub-contractors and partners to adopt its\ commitment to safety and health. The result is exceptional safety performance.

QUALITY

Rotaj Aluminium’s continued success can be attributed to the high standards it sets for itself in regards to quality of work and performance. Rotaj Aluminium has instilled values in its employee and created

a culture where quality takes dominance over every other activity. As a result, Rotaj Aluminium is highly recognized for providing its clients with maintenance-free projects and delivering high quality projects before the set deadlines. This has led to satisfied customers who choose Rotaj Aluminium as their prefered construction & Industrial partner.

Rotaj Aluminium practices “Quality in construction & Industry” methods to ensure all our work is done right, complte and free of defects first time. This in-house program is our way of making sure projects go beyond being just “good enough” and exceed the expectations of customers. This is achieved by holding pre-installation meetings and conducting inspections during the critical path of projects including first delivery of materials, first equipment installations, mock-ups, benchmarks for each type of work, and closure of utility systems.

Even after the project is complte and handed over, Rotaj Aluminium conducts a quality evaluation of its work for several years after completion by sending our team of engineers to check the condition of projects. The feedback collected from these vists is evaluated and corrective actions are taken accoedingly. Rotaj Aluminium has a team of QA/QC engineers employed on every site to ensure that constructions

works are carried out as per the company’s quality policies and methodologies.

OUR VISION

Knowing and Surpass Our Customer’s Expectations empower our Employees to achieve their potential and be the best and most trusted supplier in our chosen markets providing our shareholders with a superior on their Investment.

OUR MISSION

We deliver timely, cost effective and technically efficient project solutions to the engineering-constructions industry in United Arab Emirates.

SCOPE OF OUR ACTIVITIES

Fabrication and fixing all kinds of Aluminum and Glass

Sliding and hinges

windows & doors

All kinds of glass

reflective, clear, single, double, gorgon bar, temper, smoke…

Coating aluminum with many colors

wood finish, metallic….

Handrail & Cat Ladders

All types of railing & ladders

QUALITY ASSURANCE PROGRAM

Fabrication :

The key to our success on any job is the correct fabrication of parts by the ROTAJ plant personnel. The quality control begins with the training and supervision of qualified tradesman who are given precise instructions regarding their specific tasks. Each worker is directed to check all previous work and discuss any potential problems or unacceptable work with a supervisor. The plant foreman monitors each individual’s work on a continuous basis.

Sealant Application :

When any sealant application is initiated for a particular part, that work is reviewed and monitored by supervisory personnel. The shop-applied sealant is verified to be compatible with the “field-applied” sealant that it may be in contact with at the job site. For custom designs, the sealant manufacturer is contacted for input on the proper use of sealant in particular detail. Surfaces are cleaned with MEK or other approved cleaning solvents and wiped clean with a lint-free cloth to remove any surface contaminants. Surfaces are primed if necessary before sealant application.

Shop Water Leak Test :

A water leak test procedure is implemented to assure that the shop sealant is correctly applied and performs its intended function. This test shall be performed at regular intervals during the course of fabrication. It shall be used on gutters, end dams and other shop fabricated members where the test would be appropriate. All weep holes are plugged with tape or other stopper. The unit stands in a vertical position and the contained portion is filled with water. Visual inspection is made for leaks after two hours.

Materials requiring inspection :

A. Aluminum Extrusions

B. Glazing Gaskets

C. Setting Blocks

D. Vertical Glass Spacers

E. Stainless steel profiles

Calipers and/or a micrometer are used to test the aluminum extrusions wall thickness, pocket depths, race ways, various snap engagements and any other dimensions and/or fits that are unique to that extrusion. Structural calculations are performed based on the design and this review confirms that all structural extrusions will perform to the required design load. A square is used to check the angularity of the extrusions. If the extrusions are in tolerance, a sample is built and the fits are tested with adjacent extrusions. Only the ROTAJ engineering department can approve any sample metal for production runs. Once the engineering department has approved the sample metal, the extruder is notified of any changes or comments and advised to incorporate these revisions into the final production material order.

Spot checks are performed after the production material has been delivered to the ROTAJ plant. The checks are made by ROTAJ engineers and plant supervisors. If unacceptable material is detected at this time, the material will be replaced by the extrusion supplier. All anodize and paint finishes are inspected for consistency of surface application and tested for hardness and thickness of the applied finishes. ROTAJ only uses paint applicators that have been approved and licensed by the paint manufacturers who have been chosen on the project.

Only glazing materials that have passed mock-up testing are used on ROTAJ projects. Materials are submitted to the customer to assure compatibility with any sealant that is being used for the project. A twelve-inch-long sample of each gasket extrusion is forwarded to our customer on each project. The gaskets should be tested with all relevant sealant that is being used on the job to verify compatibility with the required application. The gasket manufacturer checks all tolerances against die drawings before the gasket extrusions leave their facility.

During the development of any new gasket design, our engineers work with the glazing gasket manufacturer’s technical personnel in designing the new gasket for proper glazing pressure and other variables that comprise a properly designed glazing pocket detail. The glazing materials that are used are ordered specifically for each project to insure that fresh extrusions are used. Production materials are shipped directly to the jobsite for installation, in most cases.

Fabrication Review :

All fabrication of materials is performed per approved ROTAJ shop drawings. ROTAJ builds custom tooling where practical to assure uniform precision and speed in the fabrication process.

Material Hardness :

Raw material extrusions are tested for the proper temper during the fabrication phase. This check is performed using a “Webster” tooling apparatus.

ROTAJ quality assurance program consists of three separate phases. The Design Phase is the initial focus in which our engineering department coordinates the contract document information with the products that ROTAJ will be supplying. The Raw Material Inspection phase includes the review of sample metal for new extrusions to verify that material is within the tolerances and standards required by the industry and established by ROTAJ. The final phase is the Fabrication Review. Our plant personnel constantly observe the finish quality, weather tightness of sealed parts, fitting of fabricated members etc., to detect any potential problems that may develop during the production process.

Previous test cases and time proven methods form the basis of the ROTAJ Quality Control Standards. A criterion is set forth and established during the initial setup phase of the job. The programs vary for different ROTAJ products and will insure the highest quality for the long-term performance of our designed systems. These quality control procedures include the inspection of raw material, fabrication and review of various manufacturing processes. They are performed well in advance of delivery of fabricated materials to the jobsite. The close attention to detail from the very beginning has allowed ROTAJ to achieve complete customer satisfaction project after project.

Design Phase :

ROTAJ is consistent in its design approach to those projects that utilize existing systems and those that require new designs. Aesthetics of the system may change, but proven methods of protection against air and water infiltration are employed on each job. Every job condition is analyzed for structural compliance with the governing building code.

After a design is established on each project, it is checked by other engineering staff members for structural integrity, and protection against water and air infiltration. The production department is consulted for comments regarding the installation of the designed system at the jobsite. We also check with our customers concerning filed-installation procedures to minimize job-site problems.

ROTAJ sets a goal on each job to produce a set of shop drawings that is second to none in our industry. Our policy is that a well-prepared set of shop drawings leads to engineered systems that can be fabricated correctly and installed properly on the building. ROTAJ has a Professional Engineer staff that works with the design team on all projects. Structural calculations prepared by a registered engineered are submitted on all ROTAJ projects whether required by specifications or not.

RAW MATERIAL INSPECTION :

All critical new extrusion dies are checked by the ROTAJ engineering department before production orders are released. This serves two purposes. Any errors on the die drawings are detected and can be corrected before production material is received in the plant. Also, this check is verification that the extrusions are held within the tolerances established by ROTAJ at the time of design.

METHOD STATEMENT

RAW MATERIAL INSPECTION :

The Purpose of this Method Statement is to outline the materials, the fabricated aluminium glazed unites for curtain wall, windows and doors and the method used in obtaining high quality installed curtain wall, windows and doors.

REFERANCE

- Project Technical Specification

- Approved Shop Drawing

- Quality Assurance Program

HEALTH AND SAFETY HAZARDS:

Specific safety measures have to follow as applicable, and all the safety measures are covered separately in the project safety plan.

RESPONSIBILITIES:

The Project Engineer is over all responsible for the implementation of method statement and ensures that his team is aware of this method statement and the all resources – human, material and equipment’s are available to carry out the work as planned and without any delay.

The Project Engineer is responsible to carry out the work as per the approved shop drawings, method statements, and co-ordinates with project parties and ensure all Windows openings, Door openings, Curtain wall openings and all necessary Information.

QA/QC Engineer is responsible to ensure work has been done as per the specification and drawings; inspections are done as per Quality Control Procedure. The Safety Engineer is responsible to ensure that all Safety precautions are in place, and that all personal on site are using the required Personal Protective Equipment’s like – Helmet, Gloves, Shoes, and Coveralls. We will also ensure all relevant permissions are

available for the works.

PROCEDURE / METHOD TO BE EMPLOYED:

Materials Approval:

The Client shall approve all Material.

• Aluminium extruded sections

• Architectural Ironmongery/Finish Hardware

• Automatic Door Operators.

• Aluminium Powder coating

• Glass/ Glazing Material

Aluminium Extrusions

Once shop drawings are approved, profiles will be ordered and extrusions are produced to comply with American Association Specification AA6063 Alloy T5 or T6 depending on the structural requirements. As soon as Aluminium materials arrive, it delivered to the powder coating factory to apply powder coating with the RAL color specified and approved by the architect.

Units Fabrication and Assembly

Fabrication Drawing: After checking site measurements, fabrication drawings are prepared for both aluminium and glass, checked and rechecked before they are released to the factory.

Aluminium Profiles preparation: In the meanwhile the factory manager prepares all the profiles for cutting and fabrication by applying protective tape and arranges them in the right order.

Profiles Cutting: Profiles are cut to size, holes punched or drilled, accessories attached and unites assembled by crimping process.

Glass Material Preparation: After preparing glass Size drawings, it will released to the glass factory to cut glass panels as per the required sizes, applying tempering and double glazing.

Units Installation

Installation set up: Installation will start after applying one layer of internal paint.

Bench marks for elevation and building line offset marks for alignment established on each floor level. Any error is found in their location, the Contractor shall notify in writing, and installation work shall not proceed in the affected area until the errors have been corrected.

Units Arrival: When the units arrive to the site, they have to be verified and checked with the schedule, after that, they will be distributed accordingly to the schedule on the shop drawings per room per buildings, all damaged sections should be sent back to the fabrication shop.

Starting Installation: Installation begins by attaching Aluminium frames to the brackets using stainless steel bolts tapped into the Aluminium mullions, after that glass units have to be installed. Any accessories/hardware exist, it should be fixed into the aluminum frames or Glass panels (for frame less Panels) in the fabrication shop.

Applying Sealant: After fixing aluminum frames, Sealant will be applied; all mortar, dirt, dust, moisture and other foreign matter shall be completely removed from surfaces it will contact. Adjoining surfaces have to be masked when required to maintain a clean and neat appearance. Sealing compounds shall be tooled to fill the joint and provide a smooth finished surface.

All the above applies for individual window openings, door openings and curtain wall. Installation will be in unit based, for example unit (10A) will be manufactured and installed, and after that different number units will be manufactured.

Water Penetration test: A water leak test procedure is implemented to assure that the shop sealant is correctly applied and performs its intended function; visual inspection is made for leaks after two hours.

Site Cleaning: All mastic smears or other unsightly marks caused by our workmen will removed from the installed work, as well as final cleaning and washing of glass, aluminium and stainless steel

MANPOWER REQUIREMENT

- Charge hands

- Foreman

- Skilled labors

- Helpers.

MATERIAL REQUIRMENTS:

- Glazed Aluminium fabricated units.

- Aluminium Frames.

- Stainless steel and Honeycomb composite panels.

- Glazing materials like sealant silicon, gasket, screws, steel fixing

angles, bolts, etc…

EQUIPMENT REQUIREMENT:

- Scaffolding with platforms/electricity operated platform cradles in sufficient numbers for installation works.

- Electric power for hand tools.

- Material hoist – as and required.

- Tower crane – as and when required.

HEALTH AND SAFETY PROVISIONS:

- All the safe practices will be adopted during the Installation of Glazed fabricated Aluminium units.

- Where ever the special work permit is required will be taken before commencing that particular work.

- All necessary personal protective equipment’s to be used.

- Full body harness will be provided for the labors on the working platform above 2m.

- Proper access for the workers and equipment’s will be provided to the Installation of Glazed fabricated Aluminium units.

- All the machinery will be checked for its maintenance records.

- All working platform will be inspected.

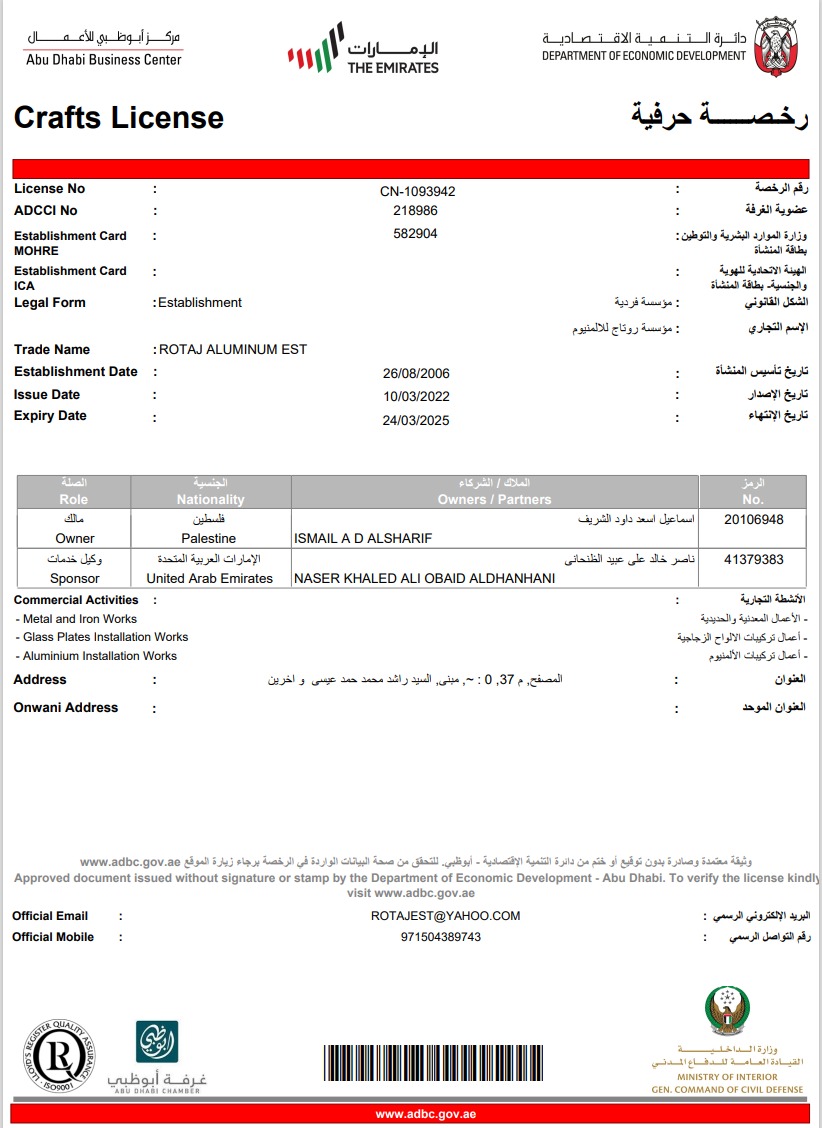

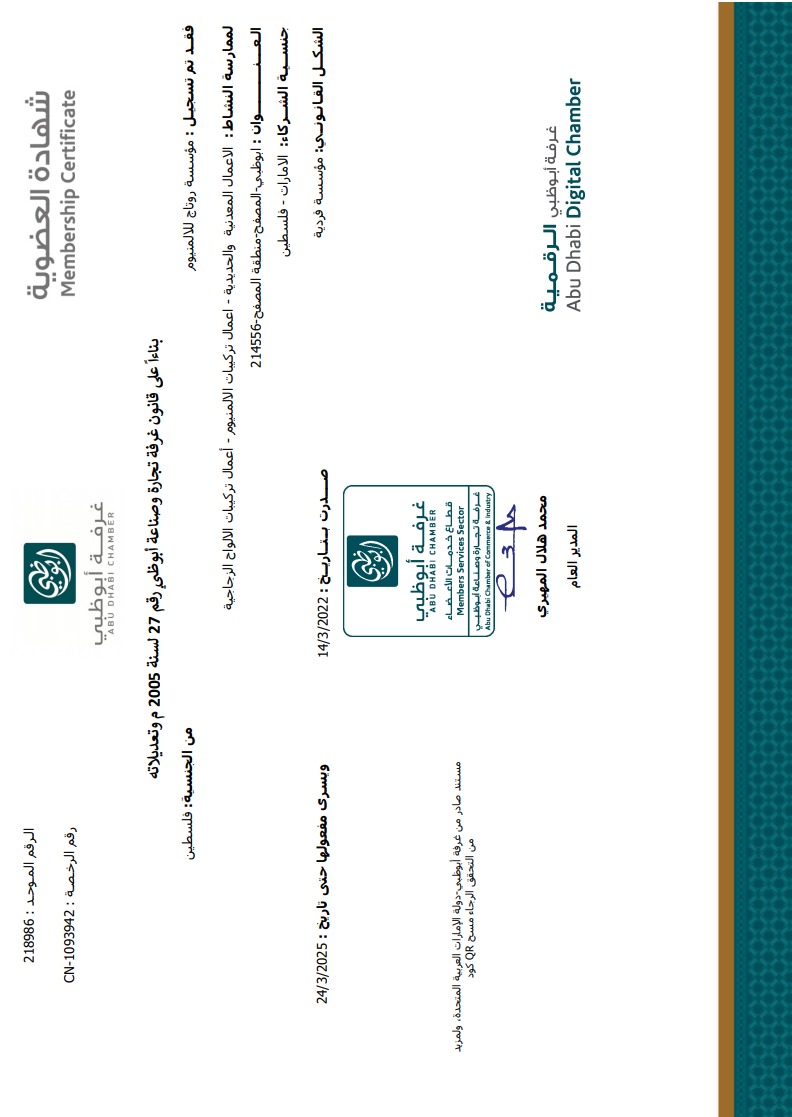

TRADE LICENSE

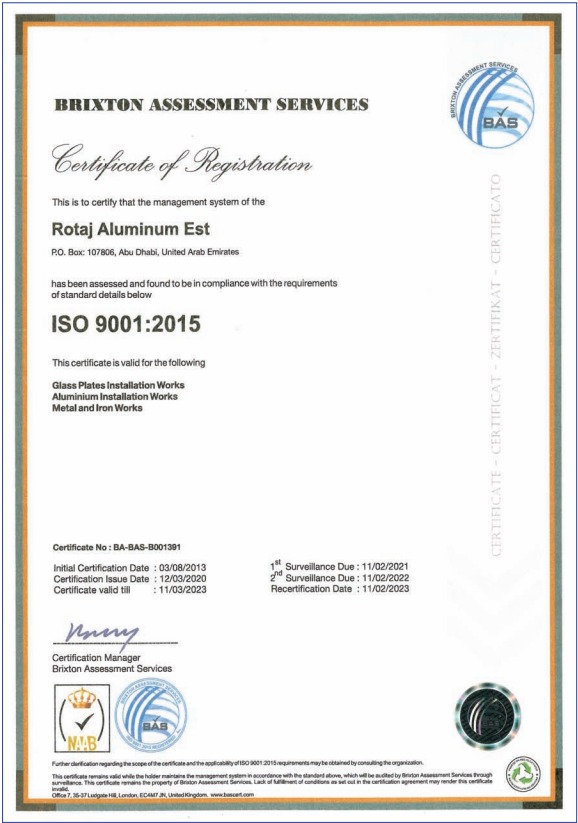

ISO CERTIFICATE

SAVIO S.P.A CERTIFICATE

OUR RECENT PROJECTS

PRODUCTS – ALUMINIUM & GLASS

CURTAIN WALL (STICK TYPE) & SKYLIGHTS

- Thermal and Non-thermal break system

- 2-4 way structural Glazing

- Supports up to 50mm thick Glazing

- Tested & approved as per ASTM/AAMA standards

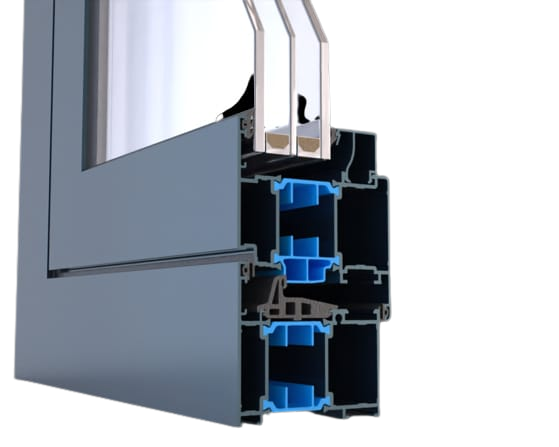

HINGED DOORS & WINDOWS

- Thermal and Non-thermal break system

- 2/3 chamber modular concept Eurosystem

- Tested & approved to international fenestration standards

HINGED DOORS & WINDOWS

- Thermal and Non-thermal break system

- 1/2/3/4 Even 8 rails sliding profile available

- Tested & approved to international fenestration standards

WORKSHOP PICTURES

STRONG PARTNERSHIP & TECHNICAL EXPERTISE

OUR BANKERS

Let’s Build Something

If you have any questions in your mind about your project like your offices, villas, and anything, always feel free to ask us.

P.O Box: 107806, Musaffah, Abu Dhabi. UAE

info@rotajest.com

+971 2 55 42 669